LMA1500-Plus Gas Turbine Power Generation Package

The LM 1500 10 MW power generation package uses a fully refurbished LM 1500 engine as its core. Each turbine is stripped down to the component level. Using OEM criteria, all components are completely and thoroughly cleaned, inspected and certified. Coupled with advanced coatings, rotor blades are balanced using American HuffmanTM balance machines, the best in the industry, to assure better than original balance in the critical rotor sections to eliminate vibration.

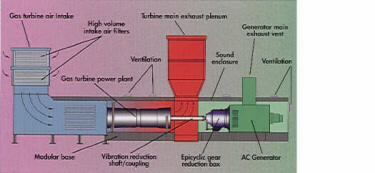

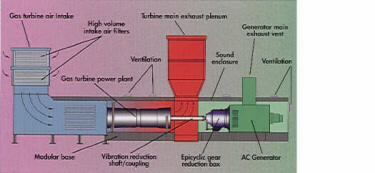

The new SermaFlowTMtype coatings mean less fouling, greater time between repair and maintaining engine efficiency longer than ever. New bearing technologies are used to supercede requirements. No surface is left unchecked; all wear parts are replaced. Coupled to the engine through an advanced coupling, designed to virtually eliminate alignment problems and minimize vibration, the power turbine connects to an epicyclic reduction gearbox, reducing engine output from 5,500 rpm to 1,800 rpm. The gearbox is in turn connected through a patented rigid mating surface to the generator; eliminating a coupling, eliminating an alignment point and eliminating a vibration point. The generator provided can be wound to your specific needs including accommodating local requirements for voltage and frequency. The generator output quality as well as safety functions and stop/start functions are controlled by a microprocessor based control package provided by one of the leading industry providers. This package provides grid synchronization as well as voltage regulation within tolerances that exceed what is normally available in the conventional grid while maintaining harmonics and distortion far superior to utility grade power.

Innovative designs extend to the auxiliaries as well including advancements in lubricating oil skid design to maximize throughput and minimize footprint through the use of modular components (which also means ease of repair and maintenance.) The starter system provides superior performance over conventional air starter designs. To accommodate environmentally sensitive areas, full sound enclosures can be provided as an option which include gas detection and fire detection/suppression systems. Air inlets can be equipped with optional advanced filtration for high dust loaded area as well as sound suppression baffles. Exhaust gases can be treated with optional selective catalytic reduction units to meet local air quality management district regulations. You can control the final configuration of the package to suit your project requirements.

STANDARD EQUIPMENT:

RATING:

| Power Output @ ISO Conditions | 10 MW continuous & 11.5 MW peak |

| Btu/shp-hr | 7,800 |

| Btu/kW-hr | 12,000 |

| Exhaust Gas Temperature | 800° F. |

| Exhaust Gas Flow | 160 lb/sec |

| Power Turbine Speed | 5,500 rpm |

| Shaft Horse Power | 15,500 |

| Fuel requirements | Distillate and/or Natural Gas |

| Power Factor | 0.8 (Typical) |

| Gas Generator | 17 Stage Compressor – 3 Stage Turbine |

| Power Turbine | Single Stage |

MAJOR EQUIPMENT COMPONENT SUPPLIERS:

| Gas Turbine | Modified G.E. LM1500 |

| Generator | Ideal Electric or equiv |

| Inlet/Exhaust system | Universal Silencer or equiv |

| Controls | GE Global or equiv |

| Reduction gearbox | Lufkin Gears or equiv |

OPTIONAL EQUIPMENT:

NOTE: The following is a PDF file and so if you do not have Adobe Reader please go to www.adobe.com and download the free viewing software.